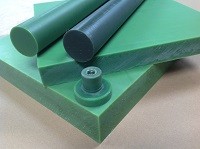

This month we thought we’d delve into the whole oil filled nylon thing. We dig into it to see what the pros and cons are and also to see if it really lives up to the hype.

The Basics

Essentially it’s a cast nylon6, without going into too much detail, it means it’s made by pouring the heated nylon polymer into rod or sheet moulds which is then allowed to cure before annealing, it’s obviously a lot more complicated than that but you get the picture.

What is unique about Oil filled nylon though is the liquid oil based lubricant which is cleverly mixed in at the beginning.

Is it old engine oil?

We asked the question and the answer was that it’s pretty much a trade secret and they could tell us but they would have to kill us, so we settled for “it’s definitely not old engine oil” the manufacturers did confirm that the oil is evenly distributed throughout the material

Why is it often pea green?

Nothing flash or fancy about that, typically it’s down to a marketing/identification thing when it was first invented. It’s great for us because it makes it easy to identify components that are made from it and adds a bit of colour to our warehouse racking. What you may also notice though is that the colour isn’t super consistent, its slightly darker on the inside due to the annealing process and you also get plenty of shade variation from batch to batch, which is lucky the nylon factories aren’t in the fashion business.

What does the data sheet tell us?

Looking at the lab test data sheets, as you would expect most of the numbers are very similar to nylon 6 until you get to 2 very important values, coefficient of friction and wear rate. Coefficient of friction is outstanding and more than twice as good as standard nylon and the wear rate which seems is four times better, that’s pretty impressive stuff.

Down to business

Does it really work? Well from the feedback we’ve had over the years, the answer seems to be definite yes and one customer a few years ago tracked it and confirmed he was getting four times the life span. So where a black nylon bearing block was lasting him six months, he was managing to get two years out of them. You could argue that this is potentially not great for a company that sells engineering plastics, particularly for its nylon sales but

One other comment seems to be that it makes things quieter in operation, so no more squeaking

So what’s the downside?

Essentially it’s a nylon 6 so no real great issues there other than its typical moisture absorption and care required when machining but all that’s pretty much par for the course. Which just leaves the price then, on comparison its approximately 10% more expensive than black nylon which isn’t huge considering the potential of four times the life span.

Availability

Size range is pretty much the same as normal cast nylon, this means though that anything thinner than 10mm sheet is a bit tricky and anything less than 50mm diameter has to be machined down at the factory. Because Oil filled nylon is a little off the beaten track as they say, stocks are not always huge so large quantity orders have been known to take two or even three weeks but there’s usually enough stock in our warehouse to keep production moving

Food Safety

The standard grade is not surprisingly not food contact compatible but the manufacturers are able to make a food safe grade on application, it will take a few weeks however depending on the volume and a few other variables

Conclusion

If we were going to make a high wear component for ourselves, we’d opt to pay the few quid extra and use Oil filled nylon but often its not our money and we’re working to a tight budget. You may also want to factor in the fact that if its lasting four times longer, orders for potential replacements are going to be a bit less frequent but your customer is going to think you’re a hero.